Since the first use of railway steam locomotives (1804, Richard Trevithick) and the burning of coal for electricity generation, great amounts of coal slag and fly ash are produced causing environmental problems requiring recycling and remediation.

At RemTech 2020 conference, Ugo Bacchiega presented a detailed study of a large historic coal slag waste deposit along the Ferrara railway station in the Italian Alps. Soil drillings, monitoring wells, trench, geophysical surveys, and chemical analysis show the size and composition of a body of soil, ground water and waste, contaminated by heavy metals and hydrocarbons. It was decided to leave the contaminated materials on site, keeping them in permanent security ('messa in sicurezza permanente'), by containment with a constructed green wall of vegetated, re-enforced earth.

From a geochemical technology point of view, this coal slag is only a waste when it is stored too far away from the site where it becomes a valuable commodity. It is our task to imagine application that is efficient enough to overcome transport costs, as the coal slag is an alkaline mineral reagent, required for doing work in an acid environment.

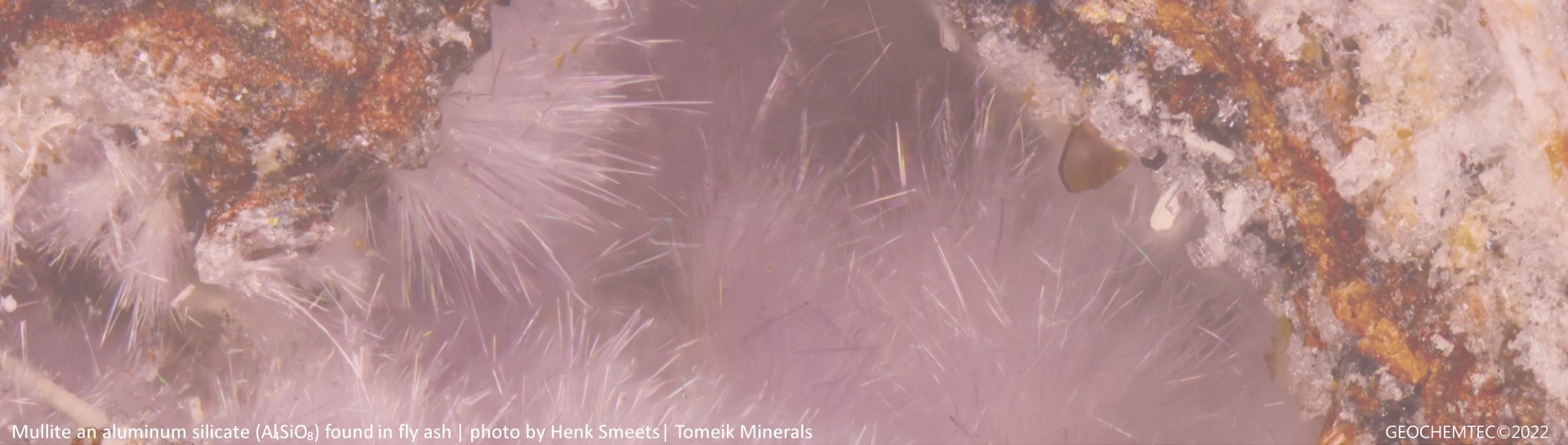

With nature as an example, we look at orebodies and think of self-sealing layers and the concentration of heavy metals herein for secondary mining. Coal slag or fly ash with hydrocarbon substrate for bacteria, when properly combined with metal sulfide mining waste, allows for recycling of metals and sequestering of carbon dioxide and mitigating climate change.